On the 1st of August 2017 a grain bin collapsed at a farm in South Indiana, USA causing a large dust explosion, luckily no one was hurt, but this accident does highlight the risks of dust explosions and how quickly they can happen.

So how did this happen? Well, the corn itself didn’t explode, but the huge cloud of grain dust generated by the collapsing bin did. This is what’s known as a dust explosion and is a serious hazard on farms as well as industries like Pharmaceutical Production, Recycling Centres, Power Generation, Wood Processing plants and many more similar industries.

In this instance as the grain bin collapsed 3 power boxes were ripped off. The grain bin trapped a concentrated amount of oxygen which, when combined with the spark from the power boxes and the dust particles, caused a rapid combustion and a resulting fire ball which can be seen in the video below.

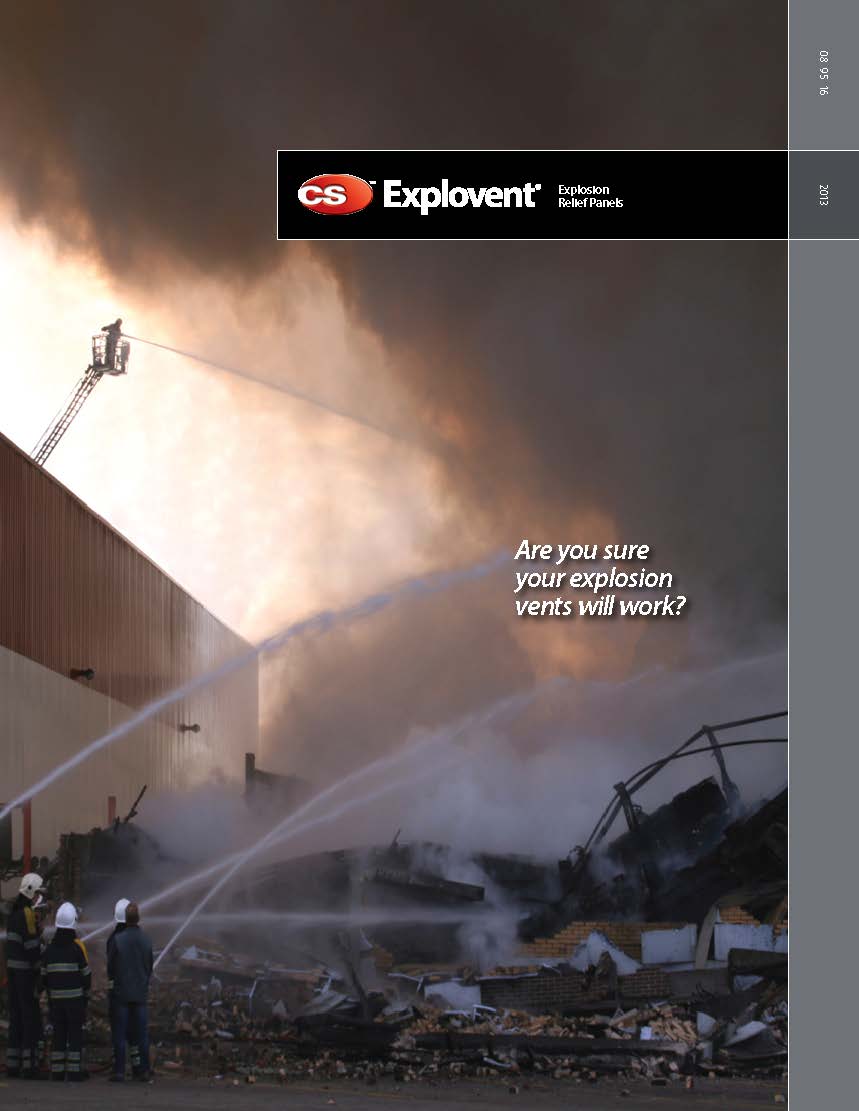

Because this explosion took place in the open air the severity of the explosion was reduced, but if it had happened within an enclosed building, the effects could have been catastrophic; resulting in severe damage to the building and significant amounts of flying debris. Just take a look at the picture below of the Imperial Sugar Refinery following a dust explosion in 2010.

If your facility is one where potentially explosive atmospheres, materials or processes exist, the UK Health and Safety Executive (HSE) provides guidance on the prevention of dust explosions. Although their article is particularly targeted at the food industry, their recommendations can be applied to most industries at risk of dust explosion.

In section 3 “Precautions against dust explosions” among other things the HSE recommends that you should

Explosion Venting Solutions

Common explosion venting solutions include shear bolts, fractionable fasteners or collapsible washers, however they do have their issues. Since they are installed in the field, they are highly dependent on proper installation on site.

Plus, they cannot be non-destructively tested or verified, the only way to know if they are installed properly and will work, is if there is an explosion event. Not ideal.

But there is a solution, developed by Construction Specialties (CS) with over 35 years of research and development in the field of specialty venting:

CS Explovent

The CS Explovent explosion venting panel system is the only field-testable and resettable explosion venting system available today. With a proven track record installed in many high profile facilities around the globe, CS Explovent offers an ATEX certified & CE marked solution to explosion venting.

The patented release mechanism is factory calibrated for release at very precise, low pressures and allows non-destructive testing as part of a regular maintenance schedule to ensure continued protection for your building and its occupants.

Explovent wall panels are designed to be the weakest part of the external structure. The lightweight panels release quickly during an explosion and once the pressure of an explosion has been relieved, the panels return to a near closed position, allowing air to return to the room and minimise the risk of implosion.